Radiator Restoration A Worthwhile Investment for Your Home Comfort and Value

Restore your radiators and improve your home's comfort,...

Metal Man Restoration LLC has provided various restoration and maintenance services to commercial, residential, institutional, retail, and hospitality facilities throughout the tri-state area for the past twenty-five years.

Our success lies not only in the experience and skills of our craftsmen, who combined has over 100 years of experience, but also in the strength of the company´s management, organization, and dedication to each project.

We are family owned and operated, so when you call, you´ll speak to someone uncommonly devoted to you, your business, your investments, your success, and your happiness.

Our track record of high achievement speaks for itself. We are committed to completing every project within our client´s budgetary constraints, on time, and in accordance with the highest quality standards.

Metal Man Restoration LLC uses the industry’s most advanced restoration and maintenance methods.

Click the button below to learn more about us, our, mission, and our team.

Our experienced craftspeople are here to answer any questions you may have about anything related to metal restoration. Contact us today for more information!

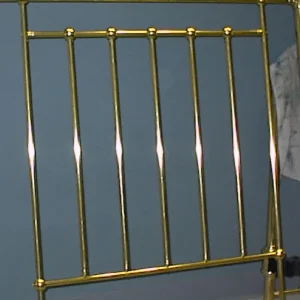

At Metal Man Restoration, we offer a wide range of metal restoration services to meet your needs. Our expert technicians are trained to restore and repair various types of metal items to their original condition, including copper cookware.

Here are some of the services we offer:

As a leader in metal restoration and fabrication, Metal Man Restoration has been providing quality services to customers in Mount Vernon, NY, and beyond for over 30 years. With over 100 years of combined experience, our team of skilled craftsmen has the knowledge and expertise to restore and repair a wide range of metal items including silver, brass, copper, pewter, steel, cast iron, wrought iron and pot metal.

At Metal Man Restoration, we pride ourselves on our attention to detail, using state-of-the-art equipment and techniques to ensure that every project we undertake is completed to the highest standard. Our team is committed to providing exceptional customer service, and we work closely with our clients to ensure that their needs are met every step of the way.

Whether you’re looking to restore an antique piece of metalwork, need help with metal fabrication or plating, or are looking for expert radiator or steel casement window restoration, Metal Man Restoration has the skills and experience to get the job done right. Contact us today to learn more about our services and how we can help you with all of your metal restoration and fabrication needs.

Metal Man Restoration stands out from other metal restoration companies in Mount Vernon, NY, with our commitment to quality, attention to detail, and 100+ years of combined experience. Our skilled professionals take pride in providing exceptional metal restoration services to our local community and beyond.

As an experienced metal restoration company in the northeast, Metal Man Restoration has gained a reputation for providing top-quality services in a variety of areas.

Our team of highly skilled technicians have decades of combined experience and are equipped with state-of-the-art tools and equipment to handle any project, big or small. We take pride in our work and are committed to providing the best results possible for our customers in Mount Vernon, NY and the surrounding areas.

At Metal Man Restoration, we understand that metal restoration needs can arise at any time. That’s why we make it a priority to be available and ready to serve our customers whenever they need us.

Our team of skilled technicians is equipped with the knowledge, tools, and equipment needed to handle any metal restoration project, no matter the size or complexity. We take pride in our ability to work efficiently and effectively to provide our customers with the best results possible.

Whether you need a small repair or a complete restoration, we are always ready to serve. We value our customers and strive to provide exceptional service and support from start to finish.

If you need metal restoration services, don’t hesitate to contact us. We are here to help and ready to serve.

Our competitive pricing ensures that our customers receive top-quality metal restoration services at a fair and reasonable price.

Metal Man Restoration offers free consultations to customers interested in our metal restoration services, allowing us to discuss your needs, offer recommendations, and provide an accurate estimate for your project.

At Metal Man Restoration, we are committed to providing unrivaled support to our customers, ensuring their complete satisfaction with our metal restoration services.

Don’t trust your priceless metal items with just any restoration company; choose Metal Man Restoration for unparalleled expertise and quality services.

Our expert artisans have decades of experience in metal restoration and provide high-quality craftsmanship to bring your metal items back to life with the latest techniques and tools, ensuring they are restored to their original beauty and functionality.

At Metal Man Restoration, we use only the highest quality materials for our metal restoration services. We understand that the materials used can greatly impact the final result, so we source our materials from trusted suppliers.

Metal Man Restoration is committed to delivering high-quality metal restoration services on time. We understand the importance of meeting our customers' deadlines and work efficiently to ensure your project is completed within your desired timeframe.

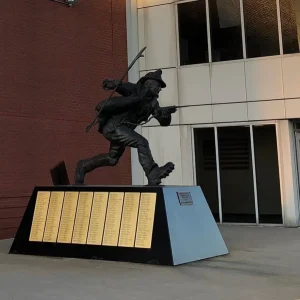

Metal Man Restoration has been trusted by some of the nation's largest and most well-known companies and organizations to provide top-quality metal restoration services, showcasing our commitment to excellence and attention to detail.

Visit our Services page to learn more about the specific metal restoration services we offer.

Our team of experts is always ready to assist you with your metal restoration needs, providing top-quality services and unrivaled support. Whether you need emergency repairs or a scheduled maintenance service, we are here to help you get the job done right, on time, and within budget. Contact us today to learn more about how we can serve you.

At Metal Man Restoration, we have developed a streamlined process to ensure efficient service and timely delivery of our metal restoration projects:

Our team will work closely with you to determine your specific metal restoration needs and discuss the project details, including timeline and budget.

We carefully assess the condition of your metal items and create a customized plan to restore them to their original beauty and functionality.

Our skilled artisans use modern techniques and tools to restore your metal items with precision and care back to their original beauty.

As the final step in our metal restoration process, we ensure timely delivery and follow-up to ensure customer satisfaction.

Don’t let your metal items go to waste – schedule your restoration appointment or come into our showroom with Metal Man Restoration today!

We are passionate about helping you metal refinshing needs at Metal Man Restoration. Whether it’s an antique heirloom, a vintage metal item, or modern machinery, we have the expertise and experience to restore it to its former beauty.

Please email us with any inquiry for quotes and attach photos by simply fill out the form on this page, or contact us using any method below, and we’ll get back to you as soon as possible. Let us help you bring your items back to life and preserve them for future generations to enjoy.

Don’t let your metal items go to waste – schedule your restoration appointment or come into our showroom with Metal Man Restoration today!

We are passionate about helping you metal refinshing needs at Metal Man Restoration. Whether it’s an antique heirloom, a vintage metal item, or modern machinery, we have the expertise and experience to restore it to its former beauty.

Please email us with any inquiry for quotes and attach photos by simply fill out the form on this page, or contact us using any method below, and we’ll get back to you as soon as possible. Let us help you bring your items back to life and preserve them for future generations to enjoy.

Excellent job every step of the way from start to finish! I researched having my vintage steam radiator restored and decided to use Metal Man Restoration based on their... read more great reputation. Anthony was a pleasure to work with, and a great communicator answering all of my questions. I knew I made a wise decision selecting this company. Manny did a wonderful and careful job moving the very large and heavy radiator paying special attention to protecting the floors. Their prices are competitive and very reasonable for the high-quality work they do. The radiator looks amazing and exceeded my expectations. I went from having a rusty old eyesore to a gorgeous antique. Highly recommend!

My husband and I purchased a copper base coffee table over 18 years ago. Over the years, the base began to darken and the beautiful patina took on a... read more blotchy brown appearance with some obvious corrosion. I did some research and found the Metal Man Restoration in Mt. Vernon, New York. I called and spoke with Anthony Guglielmo, President of the company. I sent a photo of the base and he immediately provided a quote to refinish the copper table base. Fast forward, my base looks just like it did when I first purchased it. We are so grateful to Anthony for the restoration and the level of communication during the process. The initial quote was accurate and our table is brand new. We would like to recommend this company to everyone, great results and great customer service.

Fantastic job - Anthony, Margarita and Manny were all excellent. Helpful, responsive, and easy to work with. We had three 100 year old radiator covers dipped, stripped and... read more painted and they came out like new. Also had a shower curtain rod re-chromed and looks new. HIGHLY RECOMMEND these guys.

So amazing! I had two unbelievably tarnished items for polishing. They were items that I deeply treasured but that I truly thought were beyond saving. But Metal Man Restoration came... read more to the rescue! They polished my items so wonderfully that they look better than when I originally got them. I am extremely pleased with this service. Run, don’t walk, to entrust Metal Man Restoration with your treasures. You won’t be disappointed. HIGHLY RECOMMEND.

All work done on premises at a reasonable price with impressive results. Highly recommend!

I had a 43 year old brass bed that was in terrible shape. Anthony and his team restored it to a beautiful bed again. Anthony and Manny... read more are professional, knowledgeable and responsive. It was easy to get this done. I highly recommend him and his company if you have a restoration project. I’m grateful that my bed was restored

Anthony was very responsive to my emailed inquiry. The work was done beautifully and right on his quote. It would be good if he could put a sign... read more on his door. It was worth the drive.

We moved into a very old house with radiators that were in bad shape, to say the least! I found Anthony from Metal Man and wow, amazing transformation as you... read more can see in the before pic... Truly we were astonished when they were returned to us. Pick up and delivery by Manny was seamless, with great care taken to not bump walls or furniture. My understanding is that Anthony stripped the radiators by putting them into large dipping tanks, then sandblasted them to a like-new finish, then pressure test and prime and paint with a marine primer and paint color of our choice. We wanted a cast iron look. We didn't want to hide our ratty radiators behind ugly boxes and now there are works of art in every room of our house!

My favorite place to have my radiators refurbished. I have to travel a distance to get there but it worth it.

Anthony was wonderful to do business with. He met my deadline and delivered a beautifully restored and polished antique headboard. Manny was able to pick up, deliver and restore the... read more headboard to its natural beauty. Thank you!

Restore your radiators and improve your home's comfort,...

If you're considering restoring chrome, there are a...

Nickel hardware is a great option for businesses...

The Statue of Liberty is not only a...

Metal hardness is crucial for selecting the right metal. Soft...

We serve a diverse range of clients, including homeowners, contractors, antique dealers, hardware companies, insurance companies, restoration companies, and collectors.

Sign up for Metal Man Restoration’s email list to stay updated on our latest restoration projects, news, and exclusive offers. Join our community of restoration enthusiasts today.

Do you have a metal restoration project in mind? Schedule an appointment with Metal Man Restoration today and let us bring your vision to life.